Reservoir & Mounting

I planned to recess the reservoir into the top-rear of the case, not only to make it the highest point in my system, for trapping air, but for ease of filling. I was pretty impressed by the idea of the 'liquid bombs' I'd seen in one of the Die Hard movies, and wanted the reservoir to look like it was part of the way this device might be detonated.I still have to fabricate a couple of mounting brackets that will conceal the ends of the res and hold it in place, with the final result making the res look like a clear-tube section in the centre of a steel cylinder. I also have a couple of other plans for the res...

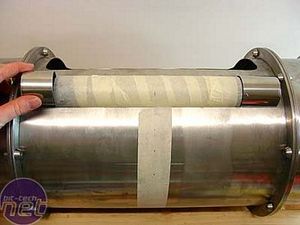

I'm using an innovatek Tank-O-Matic reservoir for the project. Not only is it superbly engineered, it's also 50mm in diameter - the same as the 50mm steel handrail I'll be using.

A big vote of thanks has to go out to Paul at CoolercasesUK, for being a great supporter of the project and supplying the reservoir (and some other parts that you'll see me using later...).

The res comes with screw fittings for 10mmOD/8mmID tube (or '8x1' as they are sometimes known), which is what I'll be using throughout. In fact, the entire cooling system, with the exception of the radiator, will be using innovatek parts, including some customising. Anyway, I digress - on with the mod!

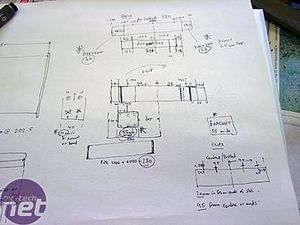

First things first - protecting my precious reservoir from scratches with a layer of masking tape. It came all the way from the UK to Australia so I wasn't about to damage it! I marked a centre point half-way along the clear section. I'd made just a few measurements and calculations to work out where everything was going to go.

Two short lengths of 50mm stainless steel handrail were cut - the same handrail I used for the cylinders on the front of the case. These were cleaned up with a file and the edges sanded smooth. The reason for the differing lengths is due to the end caps on the reservoir - the filler cap is only narrow, whereas the intake end is much wider. As I am centering the clear part of the reservoir to the opening in the back of the case, this meant I had more space at one end than the other. As these short pieces are filling in the rest of the opening, they needed to be different lengths.

I'm using the same end caps as on the front cylinders. However, these won't need to be cut down. The end caps are standard handrail fittings, bought at the same time I purchased the length of handrail.

Centering the clear part of the reservoir after marking the res and case.

Test fitting the pieces. The hole was so precisely cut by the laser that the res and end pieces sat perfectly into it (to just under half their diameter) without falling through. My arc/chord maths nightmare had paid off! However, I still needed to make sure that a knock wouldn't push anything through into the case. It was time to make some supports...

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.